LED & LCD Display Buyer's Guide: Durability, Energy Efficiency Ratio and Customized Solutions

LCD vs LED Display: Difference Between LCD and LED Display

For B-side purchasing decision makers, the core differences between LCD and LED display screens directly affect application scenarios, budgets, and long-term operating costs. The following are key comparisons:

Differences in technical principles:

LCD (Liquid Crystal

isplay):Relying on backlight (CCFL or LED) to illuminate liquid crystal pixels, suitable for static displays, such as conference room Smart Boards and industrial control panels.

LED (Light Emitting Diode): Self-luminous technology (OLED/MicroLED), providing higher contrast, commonly used in outdoor advertising screens and interactive LED Boards.

Key considerations for B-side purchasing:

Energy consumption: LED is more energy-efficient in low-brightness scenes, but high-brightness outdoor LED power consumption may surpass LCD.

Viewing angle: LED (especially OLED) has no obvious color shift under wide viewing angles, suitable for retail displays.

Cost structure: Small-size LCDs have lower unit prices, but the price difference for large-size LED screens (such as Touch Screen LED Wall) has narrowed in large-scale procurement.

Purchasing suggestions: LCD is preferred for static scenes such as medical and education; LED is selected for high-dynamic content (advertising, e-sports).

Which Is Newer: LED or LCD?

LED (especially Mini/MicroLED) is the direction of technological iteration in recent years, but LCD still dominates with its mature supply chain.

Technology Evolution Timeline:

LCD (1960s) → CCFL-backlit LCD (1990s) → LED-backlit LCD (2000s)

LED Display (1990s) → OLED (2010s) → MiniLED (2020s)

Market Status:

LCD: Still dominates the B-end market such as Smart Board and industrial control, with high cost performance and stable technology.

LED: The penetration rate of interactive advertising screens and high-end conference room LED Wall is rapidly increasing.

How to optimize the life and maintenance cost of high-brightness outdoor LED Interactive Board?

Outdoor LED screens are subject to ultraviolet rays, temperature changes, and dust corrosion, and the operation and maintenance costs can account for 30% of the total investment. The following are key optimization solutions:

1. Protection level and material selection

IP65+/IK10 dustproof and waterproof shell to prevent moisture from corroding the driver IC.

Heat dissipation: Aluminum box + external heat sink, which reduces the temperature rise by 15% compared with traditional plastic shells.

2. Operation and maintenance cost control

First 3 years: Clean the module gaps and check the power supply stability every quarter.

After 5 years: Replace aging lamp beads in batches (not the entire screen), which can save 40% of maintenance costs.

How to avoid panel uniformity and image sticking risks when purchasing large quantities of LCD Smart Boards?

Panel screening standards

Uniformity test: LCD advertising display suppliers are required to provide a 5-point brightness uniformity report (difference<10%).

Image sticking detection: Check for residue after continuously displaying a static image for 72 hours (industrial-grade LCDs should have no visible image sticking).

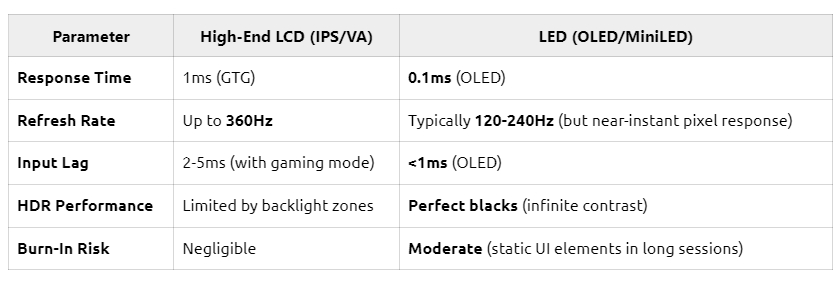

LCD vs LED for Gaming: Which Is Better?

For B2B buyers (e-gaming venues, esports arenas, commercial gaming setups), the choice between LCD and LED displays directly impacts player experience, maintenance costs, and ROI. Here’s a data-driven breakdown:

Key Gaming Performance Metrics

Can Energy-Efficient Touch Screen LED Walls Really Reduce Long-Term Costs?

Energy-saving touch LED screens can significantly reduce long-term costs through intelligent dimming, modular maintenance and long-life design. Compared with traditional display solutions, the new generation of energy-saving touch LED screens can significantly reduce energy consumption and maintenance frequency with intelligent dimming technology and optimized heat dissipation structure. Its modular design simplifies the maintenance process, while higher durability extends the product life cycle and brings lower operating expenses to commercial users. It is particularly suitable for environments such as conference centers and control rooms that require long-term continuous operation. It is a reliable choice that combines environmental benefits and economy.

Supply chain response and quality control points for customized screen requirements

ODM manufacturer screening Checklist:

Flexible production line: Can it support non-standard cutting (such as circular LED interactive screen)?

Aging test standard: High refresh rate screen requires ≥48 hours of continuous dynamic testing.

Material preparation cycle: Is the inventory of special driver ICs (such as 120Hz industrial LCD) sufficient?